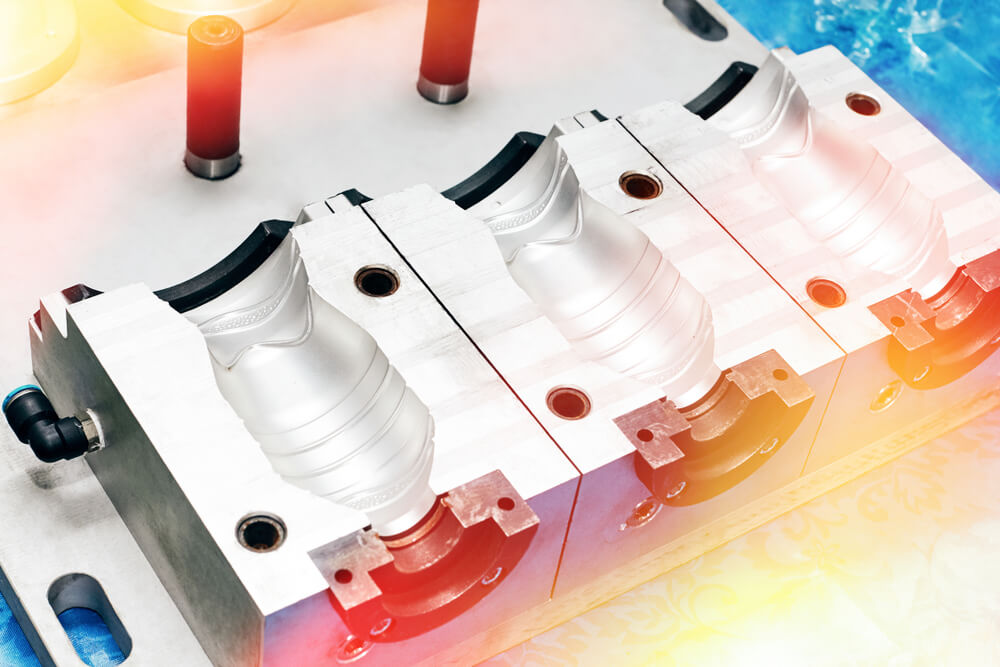

Injection molding is a widely-used manufacturing process that involves injecting molten material into a mold cavity to create solid parts. One common issue that can occur during the injection molding process is gate blush. Gate blush refers to a surface defect that appears as a visible imperfection on the finished part, typically in the form of a hazy or cloudy appearance near the gate area.

The Impact of Gate Blush on Part Quality

Gate blush occurs when the material at the gate location cools rapidly and solidifies before it has a chance to fully flow and fill the mold cavity. This can result in a mismatch in material properties, as the cooled material may have a different opacity, gloss level, or color compared to the rest of the part. Gate blush can be particularly problematic for parts that require a high level of aesthetic appeal or surface finish.

Optimizing Gate Design to Prevent Gate Blush

To minimize gate blush injection molding, it is important to understand the factors that contribute to this issue. One key factor is the design of the gate itself. A poorly-designed gate can lead to uneven flow of molten material, causing localized cooling and solidification that results in gate blush. To prevent this, it is crucial to ensure that the gate size, shape, and location are optimized for the specific part being produced.

The Role of Processing Parameters in Gate Blush Prevention

Another factor that can contribute to gate blush is the processing parameters used during the injection molding cycle. Factors such as injection speed, temperature, pressure, and cooling time all play a role in determining the flow of molten material and the as-molded properties of the part. By carefully controlling these parameters and making adjustments as needed, it is possible to minimize the occurrence of gate blush and achieve a more uniform finish.

Material Selection and Gate Blush

In addition to gate design and processing parameters, the material being used for injection molding can also have an impact on the likelihood of gate blush. Some materials are more prone to this issue than others, depending on their viscosity, flow characteristics, and thermal properties. By selecting a material that is well-suited for the specific part design and processing conditions, it is possible to reduce the risk of gate blush and achieve a higher quality finish.

Conclusion: Minimizing Gate Blush for Flawless Finishes

In conclusion, gate blush is a common issue in injection molding that can negatively impact the appearance and performance of a finished part. By understanding the factors that contribute to gate blush, including gate design, processing parameters, and material selection, it is possible to minimize this issue and achieve flawless finishes. By taking proactive steps to address potential causes of gate blush, manufacturers can improve the overall quality of their injection-molded parts and deliver products that meet the highest standards of performance and aesthetics.