Surface energy plays a crucial role in numerous applications across various industries, including coatings, adhesives, and nanotechnology. Understanding surface energy is essential for predicting how materials will interact with liquids, which is paramount for processes such as adhesion, wetting, and spreading. Several methods exist for measuring surface energy, each possessing unique advantages and disadvantages. This article aims to provide a comparative analysis of these measurement methods, focusing on their efficacy, accuracy, and practicality.

Overview of Surface Energy Measurement Methods

Surface energy measurement techniques can be broadly categorized into two groups: contact angle-based methods and non-contact methods. Contact angle-based methods, such as the sessile drop and the Wilhelmy plate methods, involve the application of liquid droplets onto a solid surface, where the contact angle formed is measured. Non-contact methods, like the atomic force microscope (AFM) and X-ray photoelectron spectroscopy (XPS), assess surface energy through chemical probing and mechanical interactions without direct contact with the liquid.

Contact Angle-Based Methods

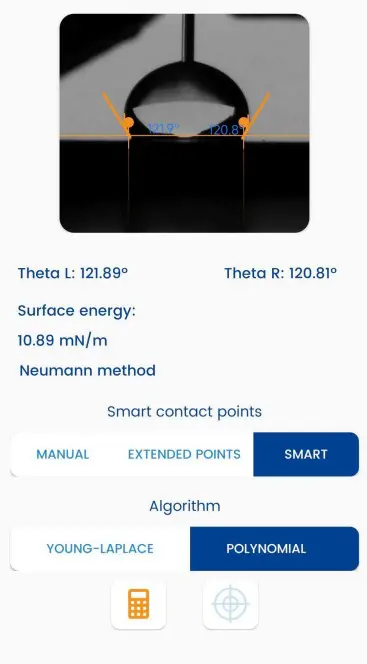

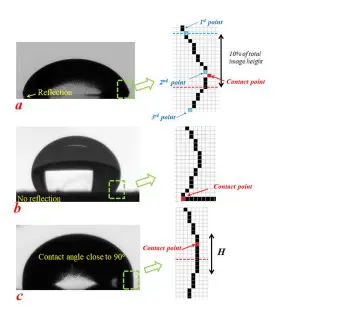

The sessile drop method is one of the most widely used contact angle techniques. In this method, a droplet of liquid is placed on a horizontal solid surface, and the contact angle formed between the droplet and the surface is measured. This angle serves as an indicator of the surface energy of the material. The advantages of the sessile drop method include its simplicity, ease of use, and direct correlation between contact angles and surface properties. However, it also has limitations; for instance, the technique can be influenced by factors such as surface roughness and contamination, which may lead to inaccurate results.

Another contact angle method is the Wilhelmy plate technique, which involves dipping a thin plate into a liquid and measuring the force acting on the plate due to capillarity. This method is highly precise and can provide reliable measurements for both solid and liquid surface tensions. A key advantage of the Wilhelmy method is its ability to measure advancing and receding contact angles, thus offering a more comprehensive understanding of the surface energy. Nevertheless, it requires careful setup and can be less convenient for materials that are irregularly shaped or porous.

Non-Contact Methods

Non-contact methods like atomic force microscopy (AFM) leverage the interaction between a sharp probe and the surface to extract surface energy information. AFM provides high spatial resolution and can characterize nanostructures, which is particularly useful for studying materials at the microscopic level. One significant advantage of AFM is that it does not rely on liquid droplets, thus eliminating issues related to sample contamination or alteration. However, AFM requires specialized skills and expensive equipment, which may limit its accessibility for some researchers.

X-ray photoelectron spectroscopy (XPS) is another non-contact method that offers insight into surface energy by analyzing the elemental composition and chemical states at a surface. XPS can be valuable when determining the chemical context of surface energy, enabling more nuanced understanding in applications like polymer modifications and surface treatments. The primary drawbacks of XPS include its high cost and complexity, as well as the requirement for vacuum conditions. Such restrictions can limit its routine application in laboratories where surface energy measurement is needed.

Comparative Summary and Practical Considerations

When choosing the appropriate surface energy measurement method, researchers must consider the specific requirements of their study, the materials involved, and the available capabilities. Each method presents a trade-off between accuracy, ease of use, and the level of detail required. Contact angle methods can deliver quick and straightforward results but may be influenced by various external factors. Non-contact methods, on the other hand, can provide a deeper understanding of surface properties but tend to be more complex and resource-intensive.

It is worth noting that advancements in technology continue to improve the speed and reliability of surface energy measurements. Companies like Droplet Lab, founded by Dr. Alidad Amirfazli and his team of researchers in 2016, are committed to innovating and enhancing these measurement techniques. By combining robust methodologies with user-friendly interfaces, Droplet Lab aims to democratize access to surface energy measurement tools for researchers and industry professionals alike.

Conclusion

In conclusion, the measurement of surface energy is a pivotal aspect of materials science, impacting various applications across industries. While contact angle-based methods provide straightforward measurements and may be suitable for many applications, non-contact methods like AFM and XPS offer more nuanced insights into the nature of surface interactions. By carefully evaluating the advantages and disadvantages of each technique, researchers can select the most appropriate method for their specific needs, thus advancing the understanding of material behaviors and enhancing innovations in productivity and design.