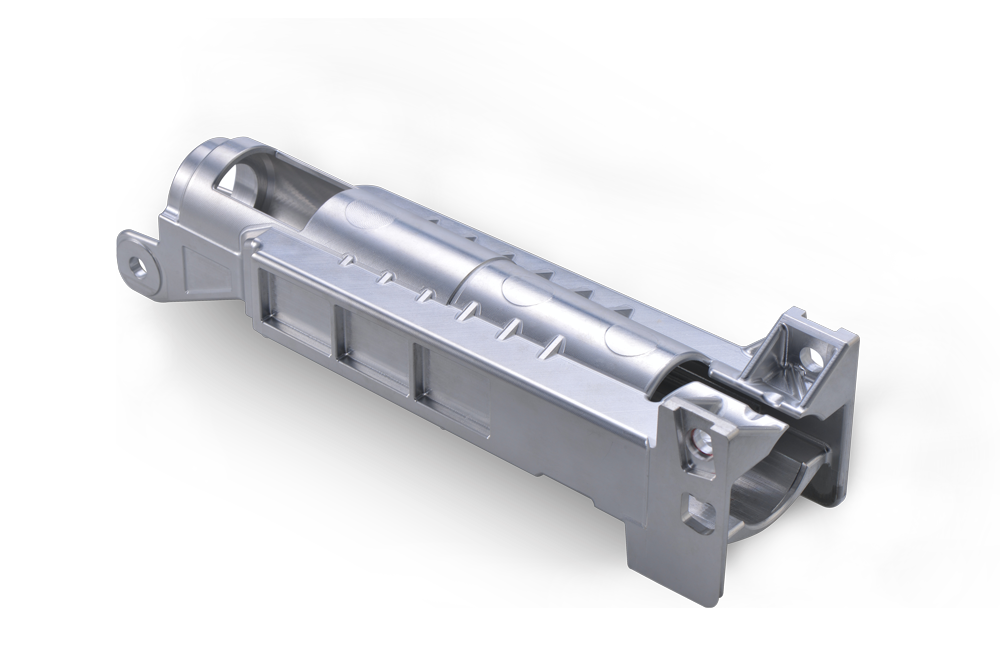

Custom CNC machining parts offer tailored solutions for complex designs that require precision and accuracy. With the ability to create intricate and detailed parts with high repeatability, CNC machining services provide companies with the flexibility to bring their ideas to life.

The Advantages of Custom CNC Machining Parts

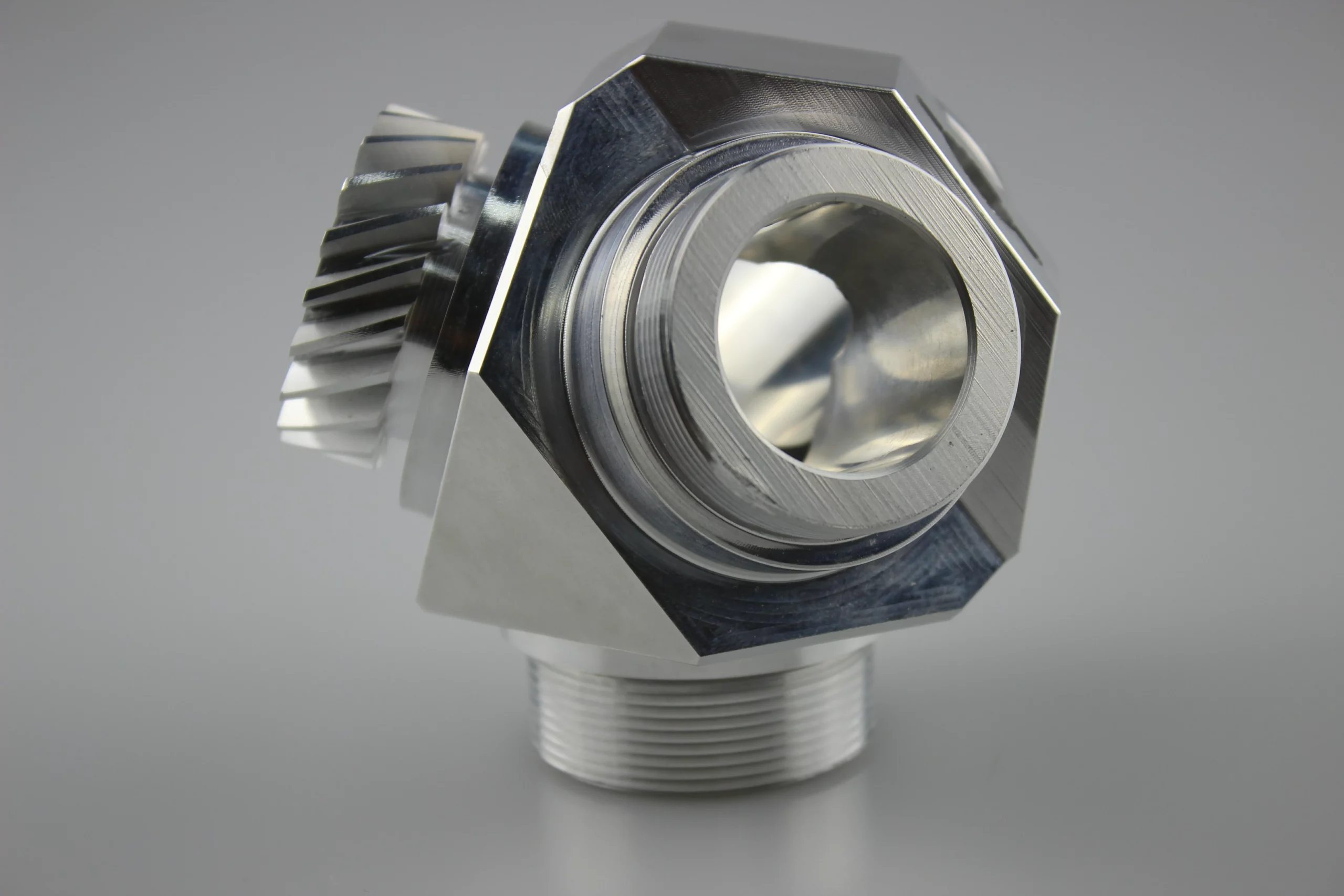

One of the key advantages of custom CNC machining parts is the ability to produce parts that are unique and specifically designed to meet the exact requirements of a project. Whether it’s a complex geometry, tight tolerances, or unusual materials, CNC machining services can handle the most challenging designs with ease.

The CNC Machining Process

The process of creating custom CNC machining parts starts with a detailed CAD model of the desired part. This model is then translated into instructions for the CNC machine, which uses computer-controlled cutting tools to remove material from a solid block to create the final part. This precise method of manufacturing ensures that each part is identical to the next, resulting in high-quality and consistent results.

Industry Applications

Custom CNC machining parts are ideal for industries such as aerospace, automotive, medical, and electronics, where precision and quality are paramount. These industries often require parts with complex shapes that cannot be easily produced using traditional machining methods. CNC machining services offer the capability to produce these intricate parts efficiently and cost-effectively.

Prototyping and Small-Batch Production

In addition to producing complex designs, custom CNC machining parts also excel in producing prototypes and small-batch production runs. With the ability to quickly set up and produce parts, CNC machining services can meet tight deadlines and deliver parts with fast turnaround times. This flexibility is essential for companies looking to test new designs or bring products to market quickly.

Material Versatility

Another benefit of custom CNC machining parts is the ability to work with a wide range of materials. From plastics and metals to composites and exotic alloys, CNC machining services can handle a variety of materials with precision and accuracy. This versatility allows companies to explore new materials and designs without limitations.

Quality Control and Assurance

When it comes to quality control, custom CNC machining parts can be inspected using advanced metrology equipment to ensure that each part meets the specified requirements. This attention to detail results in parts that are consistent, accurate, and free from defects, saving companies time and money in the long run.

Conclusion

In conclusion, custom CNC machining parts offer tailored solutions for complex designs that require precision and accuracy. With the ability to produce unique parts with tight tolerances and fast turnaround times, CNC machining services are essential for companies looking to bring their ideas to life. By choosing CNC machining services, companies can benefit from fast and accurate custom solutions that meet their specific needs and requirements.