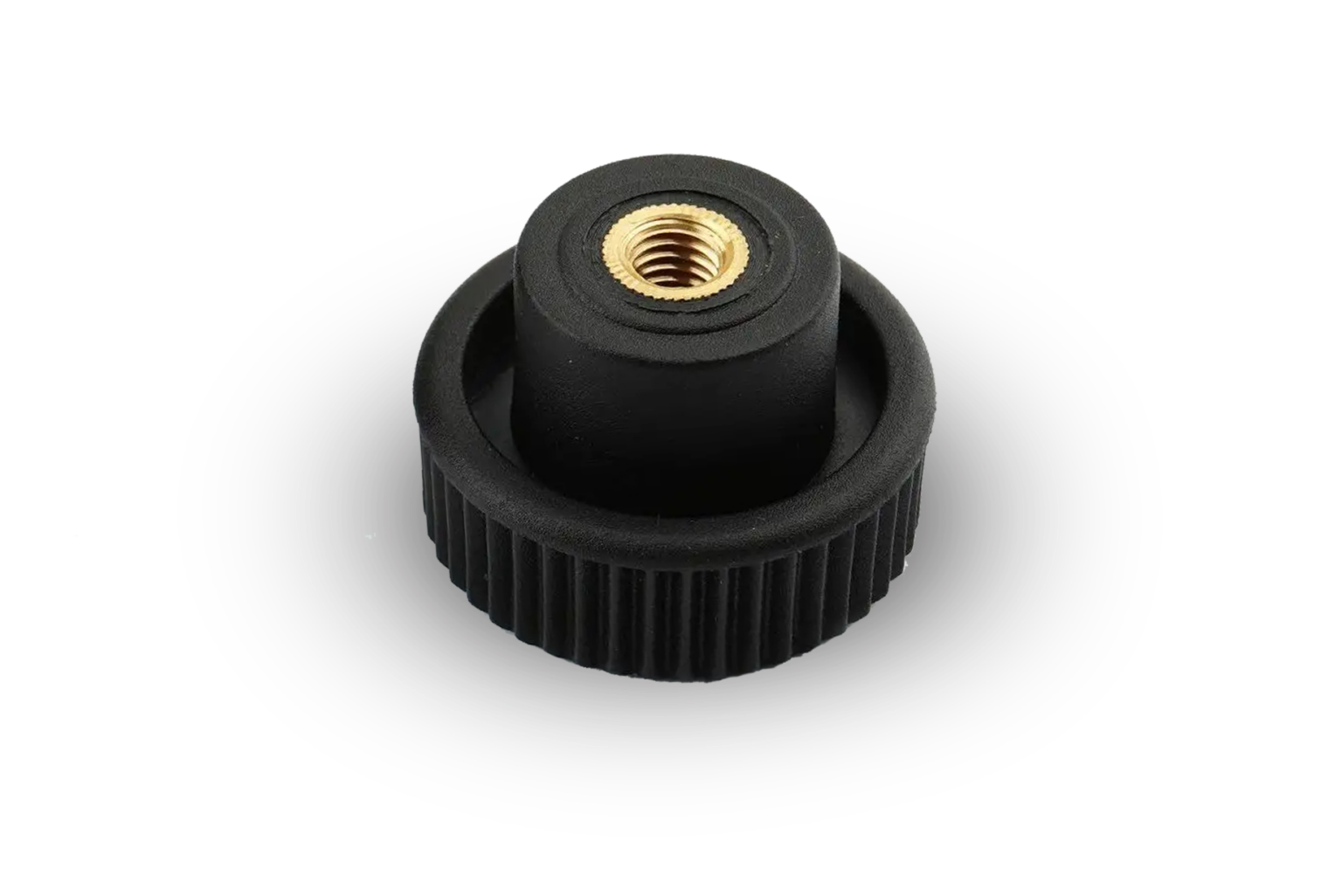

Custom insert molding services offer precision craftsmanship for complex parts that require specialized attention to detail. With this manufacturing process, a metal or plastic insert is encapsulated within a molded plastic component, creating a seamless and integrated final product.

The Benefits of Custom Insert Molding

When it comes to producing intricate parts with specific requirements, custom insert molding services are the go-to solution. This process allows for the creation of components that have unique geometries, varying thicknesses, and other complex features that would be difficult or impossible to achieve with traditional molding methods.

Enhancing Structural Integrity and Durability

One of the key advantages of custom insert molding is its ability to enhance the structural integrity and durability of a part. By incorporating metal inserts within plastic components, manufacturers can improve strength, rigidity, and overall performance. This is especially important for parts that will be subjected to high stress or pressure during use.

Cost Savings and Production Efficiency

In addition to improving mechanical properties, custom insert molding also offers benefits in terms of cost savings and production efficiency. By consolidating multiple manufacturing steps into a single operation, the process reduces the need for secondary assembly processes, minimizing labor costs and streamlining production timelines. This results in a quicker time to market for new products and a more cost-effective manufacturing solution overall.

Design Flexibility and Customization Options

Furthermore, custom insert molding allows for greater design flexibility and customization options. Manufacturers can choose from a wide range of materials for both the insert and the molded component, enabling them to achieve specific performance characteristics, aesthetics, and functionality requirements. This versatility makes custom insert molding an ideal choice for a wide range of industries, including automotive, electronics, medical devices, and consumer products.

Precision and Tight Tolerances

Another key advantage of custom insert molding services is the ability to create parts with high precision and tight tolerances. The process provides excellent control over the molding variables, resulting in consistent and repeatable outcomes. This level of precision is essential for ensuring the proper fit and function of components, particularly in applications where tight dimensional accuracy is critical.

Conclusion

Overall, custom insert molding is a versatile and reliable manufacturing process that can address the unique needs of complex parts and components. By leveraging precision craftsmanship, advanced materials, and design expertise, manufacturers can create high-quality products that meet the most demanding requirements. Whether you need to enhance the performance of an existing part or design a new component from scratch, custom insert molding services offer a solution that delivers superior results.