High-speed steel and carbide are two of the most commonly used materials in the machining industry, each with its own set of advantages and disadvantages. Machinists often have to make a decision between the two based on the specific requirements of the job at hand. In this section, we will delve into a comparative analysis of high-speed steel and carbide to help machinists make an informed decision.

Advantages of High-Speed Steel

Let’s start with high-speed steel, which has been a staple in the machining industry for many years. High-speed steel is known for its excellent toughness, versatility, and relatively low cost compared to carbide. It can withstand high temperatures without losing its hardness, making it ideal for cutting tools that encounter high-speed and high-heat applications. High-speed steel tools are also easier to sharpen and maintain, which can lead to cost savings in the long run.

Advantages of Carbide

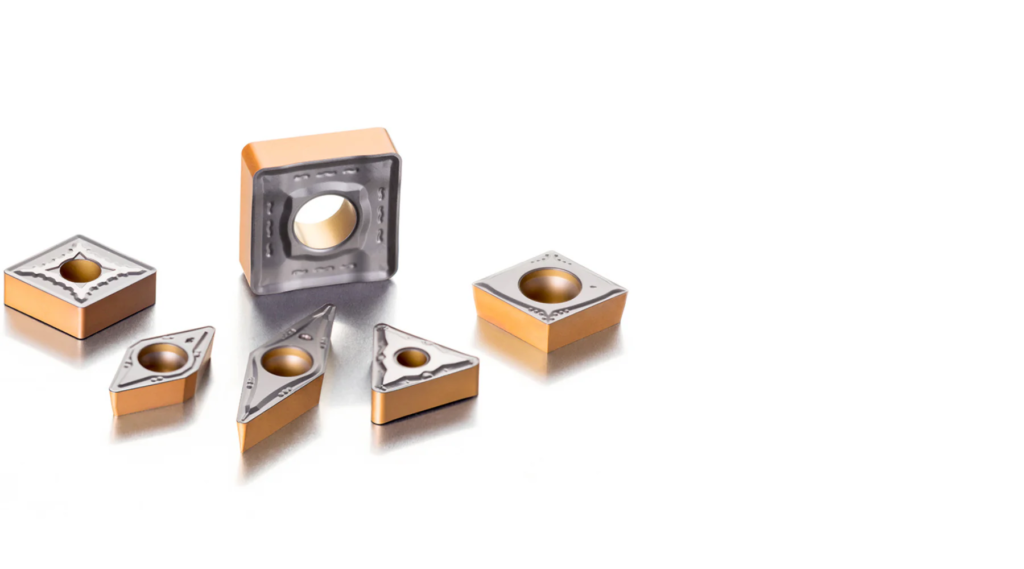

On the other hand, carbide is a newer material that has gained popularity in recent years due to its superior hardness and wear resistance. Carbide tools are known for their ability to maintain a sharp cutting edge for a longer period of time, resulting in improved machining efficiency and higher precision. In addition, carbide tools are better suited for cutting hard materials such as stainless steel, cast iron, and titanium, where high-speed steel tools may struggle.

Cost Considerations

When it comes to cost, carbide tools are generally more expensive than high-speed steel tools. While the initial investment may be higher, the longer tool life and improved performance of carbide tools can often offset the higher cost in the long term. Machinists need to weigh the upfront cost against the potential savings and benefits over time when choosing between high-speed steel and carbide.

Machining Process Considerations

Another factor to consider is the machining process itself. High-speed steel tools are more forgiving when it comes to setup and operating conditions, making them suitable for a wide range of machining applications. Carbide tools, on the other hand, require more precise setup and operating parameters to achieve optimal performance. Machinists need to take into account the specific requirements of the job, such as material, cutting speed, and feed rate, to determine which tool material is best suited for the task at hand.

Conclusion

In conclusion, both high-speed steel and carbide have their own unique advantages and limitations. High-speed steel offers excellent toughness, versatility, and cost-effectiveness, making it a popular choice for a wide range of machining applications. Carbide, on the other hand, provides superior hardness, wear resistance, and precision, making it ideal for cutting hard materials and high-speed applications.

Making an Informed Decision

Ultimately, the choice between high-speed steel and carbide comes down to the specific requirements of the job and the machining conditions. Machinists need to consider factors such as material type, cutting speed, precision requirements, and cost to determine which tool material is best suited for the task. By understanding the strengths and weaknesses of both high-speed steel and carbide, machinists can make an informed decision to optimize their machining process and achieve the best possible results.