In today’s competitive market, businesses are constantly looking for ways to enhance the durability and aesthetics of their products to stay ahead of the competition. Overmoulding services are a popular option for achieving these goals, as they provide a cost-effective way to improve the functionality and appearance of products.

The Overmoulding Process

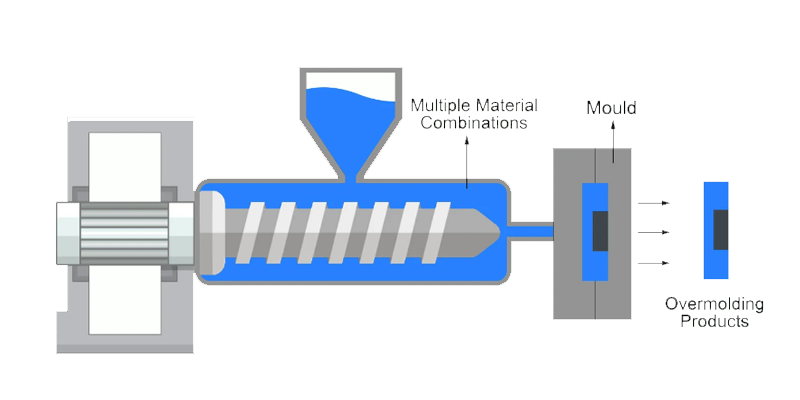

Overmoulding is a process where a layer of material is added over an existing part to enhance its performance and appearance. This process involves melting a material such as plastic or rubber and then injecting it onto the base part, creating a secure bond between the two materials. The result is a product that is not only more durable but also more visually appealing.

Improved Durability

One of the key benefits of overmoulding services is the improved durability of the finished product. By adding an additional layer of material, products become more resistant to wear and tear, reducing the likelihood of damage or failure. This is particularly important for products that are exposed to harsh conditions or frequent use, as overmoulding can help extend their lifespan and reduce the need for replacements or repairs.

Design Flexibility

In addition to enhancing durability, overmoulding also allows for greater design flexibility. Manufacturers can choose from a wide range of materials, colors, and textures to create products that are not only more durable but also more aesthetically pleasing. This customization can help products stand out in a crowded marketplace and attract more customers.

Ergonomic Benefits

Furthermore, overmoulding services can also improve the ergonomics of a product, making it more comfortable and easier to use. By adding a layer of softer material over a harder base part, manufacturers can create products that are more ergonomic and user-friendly. This can lead to higher customer satisfaction and increased sales, as consumers are more likely to choose products that are comfortable and easy to use.

Cost-Effectiveness

Another advantage of overmoulding services is their cost-effectiveness. By improving the durability and aesthetics of a product in a single step, manufacturers can reduce the need for additional processes or components, saving time and money in the production process. This can help businesses lower their overall manufacturing costs and increase their profit margins.

Conclusion

Overall, overmoulding services offer a range of benefits for businesses looking to enhance the durability and aesthetics of their products. By adding a layer of material over an existing part, manufacturers can create products that are more durable, visually appealing, and user-friendly. This can help businesses stay ahead of the competition and attract more customers, leading to increased sales and higher profits.