As the demand for aseptically filled products continues to rise across industries such as pharmaceuticals, biotechnology, and food and beverage, the future of aseptic filling is ripe with emerging trends and market opportunities. Companies are constantly seeking ways to improve efficiency, reduce costs, and enhance product quality in their aseptic filling operations.

The Rise of Robotics and Automation in Aseptic Filling

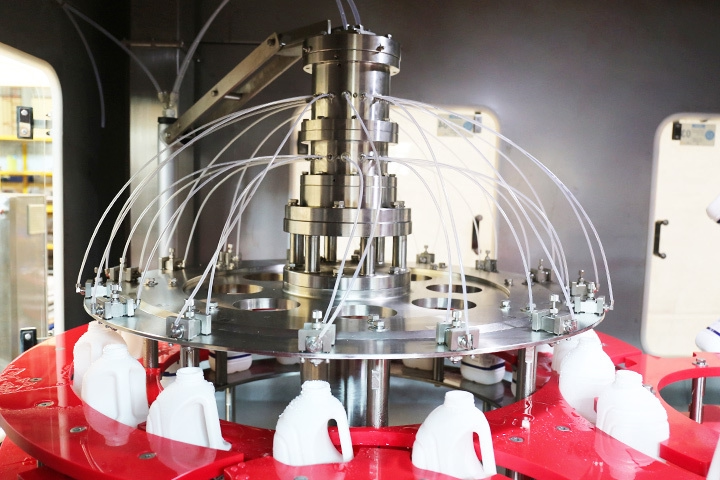

One of the key emerging trends in aseptic filling is the integration of robotics and automation technologies. These technologies are revolutionizing the way aseptic filling operations are conducted, allowing for greater precision, speed, and consistency in the filling process. Robots can handle delicate tasks with a level of accuracy that humans simply cannot match, leading to improved sterility and product quality. Automation also helps to reduce the risk of human error, which can be a major concern in aseptic filling operations.

The Benefits of Single-Use Technologies in Aseptic Filling

Another trend that is gaining momentum in aseptic filling is the use of single-use technologies. Single-use systems eliminate the need for cleaning and sterilization of equipment between batches, reducing the risk of cross-contamination and minimizing downtime. These systems are also more cost-effective than traditional stainless steel equipment, as they do not require costly maintenance and validation processes. Additionally, single-use systems are more flexible and can easily be scaled up or down to meet changing production demands.

Advancements in Material Science: Enhancing Product Integrity

Advancements in material science are also playing a key role in shaping the future of aseptic filling. Manufacturers are constantly developing new materials that offer improved barrier properties, chemical resistance, and durability. These materials help to ensure the integrity of aseptically filled products throughout their entire shelf life, protecting them from contamination and degradation. Innovations in material science are also leading to the development of more sustainable packaging solutions, which are becoming increasingly important in today’s environmentally conscious market.

Regulatory Compliance: A Growing Concern in Aseptic Filling

On the regulatory front, the aseptic filling industry is facing increasing scrutiny from regulatory bodies around the world. As a result, companies are investing more heavily in quality control and assurance measures to ensure compliance with stringent regulatory standards. This has led to the development of advanced monitoring and validation technologies that provide real-time data on the sterility and quality of aseptically filled products. These technologies help companies to identify and address potential issues before they escalate into larger problems, reducing the risk of product recalls and regulatory fines.

Market Opportunities: Growth and Innovation in Aseptic Filling

In terms of market opportunities, the global aseptic filling market is expected to continue growing at a rapid pace in the coming years. The increasing demand for aseptically filled products, coupled with advancements in technology and regulatory compliance, is creating lucrative opportunities for companies operating in this space. Manufacturers that can innovate and adapt to changing market dynamics will be well positioned to capitalize on the growing demand for aseptically filled products.

Conclusion: A Bright Future for Aseptic Filling

In conclusion, the future of aseptic filling is bright, with emerging trends and market opportunities driving innovation and growth in the industry. Companies that can stay ahead of the curve by embracing new technologies, materials, and regulatory standards will be well positioned to succeed in the aseptic filling market of tomorrow.